PCBA Test & Ticket Services

Do you need PCBA testing but don't have a tester?

At Acculogic, we understand that having in-house testing equipment is not always feasible. That's why we offer fast, reliable, and affordable PCBA testing services to help companies ensure product quality.

Our PCBA (Printed Circuit Board Assembly) testing services are designed to ensure the highest quality and reliability of your electronic products. If you have a test program and fixture but lack a tester or need complete turnkey test services, we can work closely with you to support your production test requirements. We offer a comprehensive range of testing solutions, including:

- In-Circuit Testing (ICT): Verifies the functionality of individual components on the PCB Using Teradyne and Agilent in-circuit testers.

- Flying Probe: Identifies defects such as soldering issues, incorrect component placement and faulty connections

- Functional Testing: Simulates the operational environment to check the overall performance of the assembled board.

Our team of experienced engineers tailors each testing program to meet your specific requirements, ensuring thorough evaluation and high-quality results. By leveraging our state-of-the-art equipment and expertise, you can confidently deliver robust and high-performing electronic products to your customers.

Your boards. Our test services.

Acculogic test and diagnostic techniques

- Ensure that the electrical continuity of the board is intact.

- Generate precise test patterns to simulate operational conditions.

- Perform in-depth failure analysis to prevent future issues.

- Use test and measurement tools to validate each aspect of the PCB design.

- Conduct comprehensive circuit board diagnostics at various stages to ensure long-term reliability.

Our Test. Your ticket.

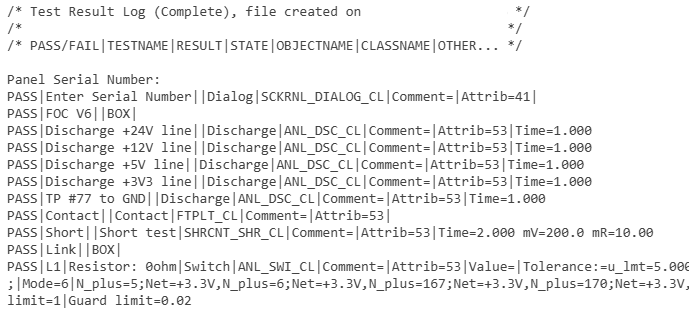

One of the key features of the Test and Ticket service is the ability to efficiently document and track defects. When a fault is detected, Acculogic’s system automatically generates a ticket that provides detailed information about the type of defect, its location, and the necessary repair actions. This ticketing system provides several benefits:

- Detailed Diagnostics: The system pinpoints the exact component or area of the PCB where the fault occurs, reducing guesswork and enabling faster repairs.

- Repair Instructions: Technicians receive clear instructions on how to fix the issue, ensuring consistency and reducing the risk of human error during rework.

- Data Tracking: Manufacturers can track the number and types of faults occurring on each PCB, which helps in identifying recurring issues and improving manufacturing processes.

This systematic approach to fault tracking and repair helps streamline the process and improves overall efficiency.