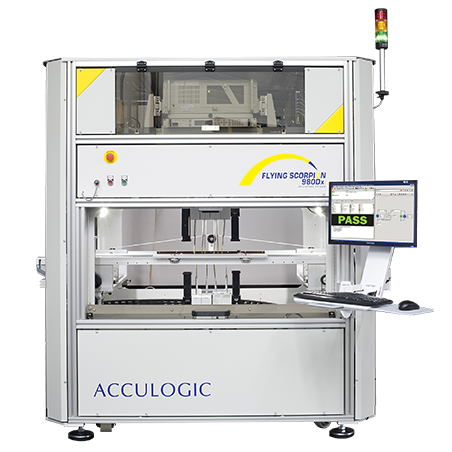

SCORPION FLS980Dxi Semiconductor Load Board Testing

Ensuring Quality Through Comprehensive Load Board Testing.

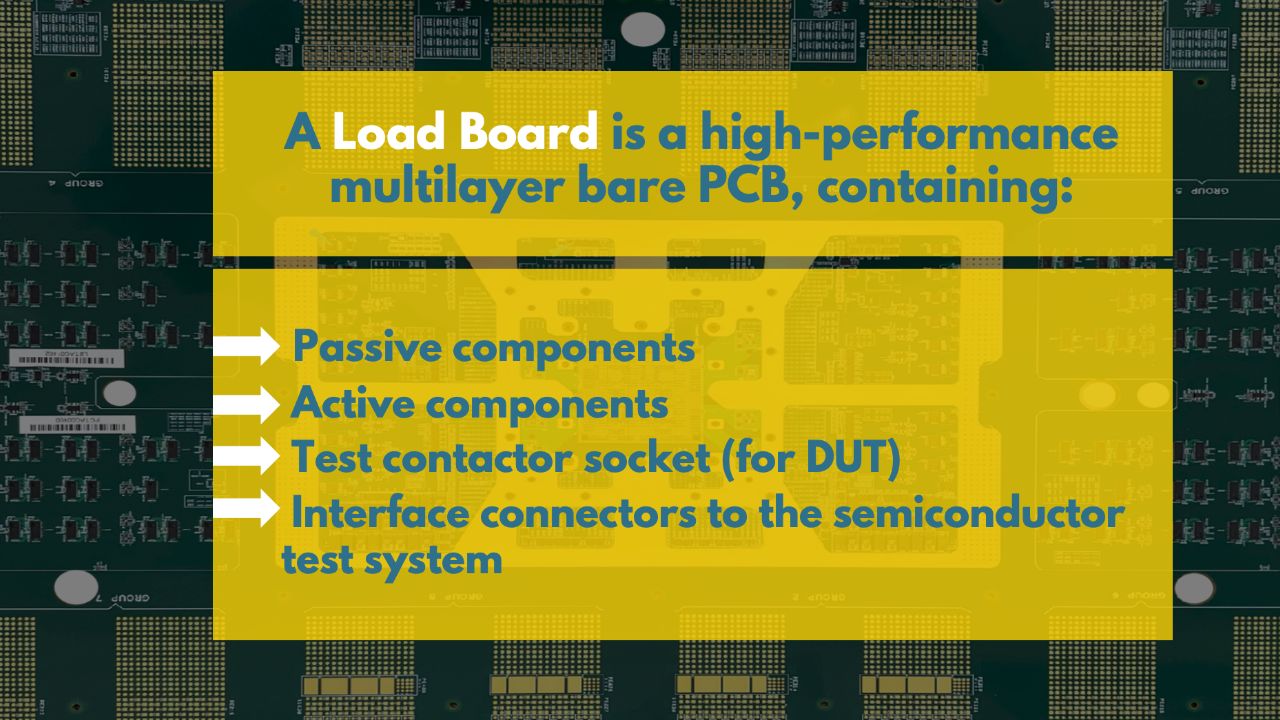

What is a Load Board?

A semiconductor load board is a high-performance, multi-layer circuit board used to test semiconductor devices during production. It is designed to interface with the semiconductor device and the test equipment to perform electrical tests on the device and verify its functionality, performance, and reliability. The load board provides a connection between the device under test and the test equipment, allowing for the application of electrical signals and measurement of device responses. It is an essential tool for semiconductor manufacturing, ensuring the quality and reliability of the devices before they are shipped to customers.

Load Board Test Challenges

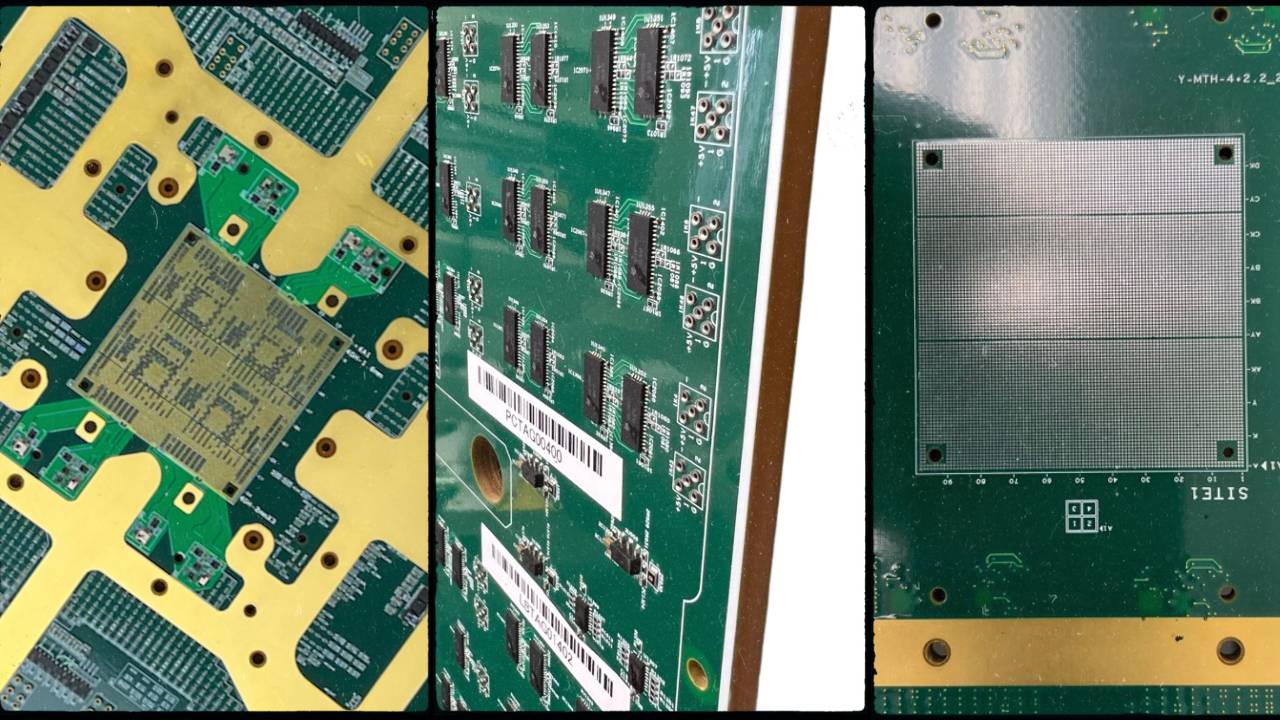

- ➡️ Bare PCB is tested after fabrication before any components are placed on the board. PCB can be damaged during the component placement processes.

- ➡️ Defective components can have placement/infant mortality failures

- ➡️ Connector can be misaligned/damaged during installation.

Load Board Complexity

Load Board – Bare PCB Tests

Netlist Verification

Leakage Tests

Measure current between nets

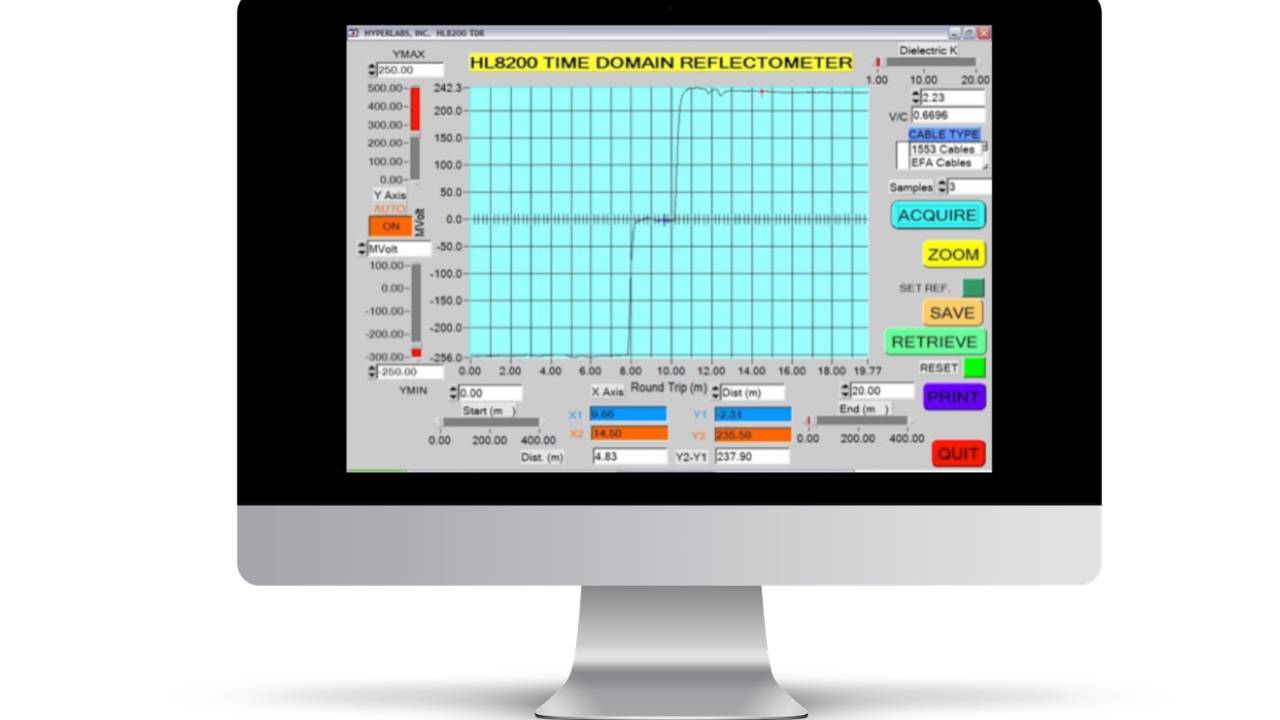

Time Domain Reflectometry

Example of TDR Measurement

Load Board – Component Tests

- ▫️ Shorts testing – verify power nets have no shorts

- ▫️ Shorts testing – ensure selected nets have no shorts

- ▫️ Passive tests – resistors, capacitors, diodes…

- ▫️ Active tests – FETs, LEDs, Regulators…

- ▫️ Relay test - measure switching time

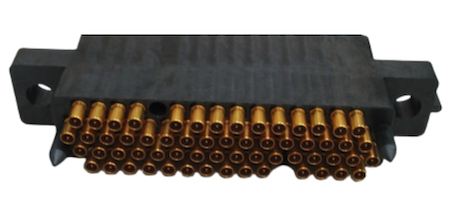

- ▫️ Connector tests – signal and shield continuity

- ▫️ Planarity test – measure component heights

- ▫️ Programmable devices – read and write functions

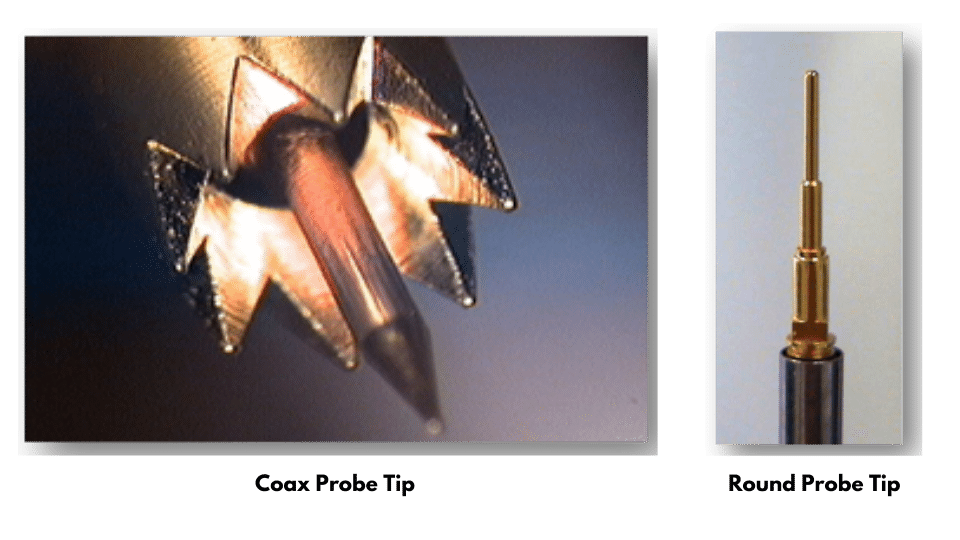

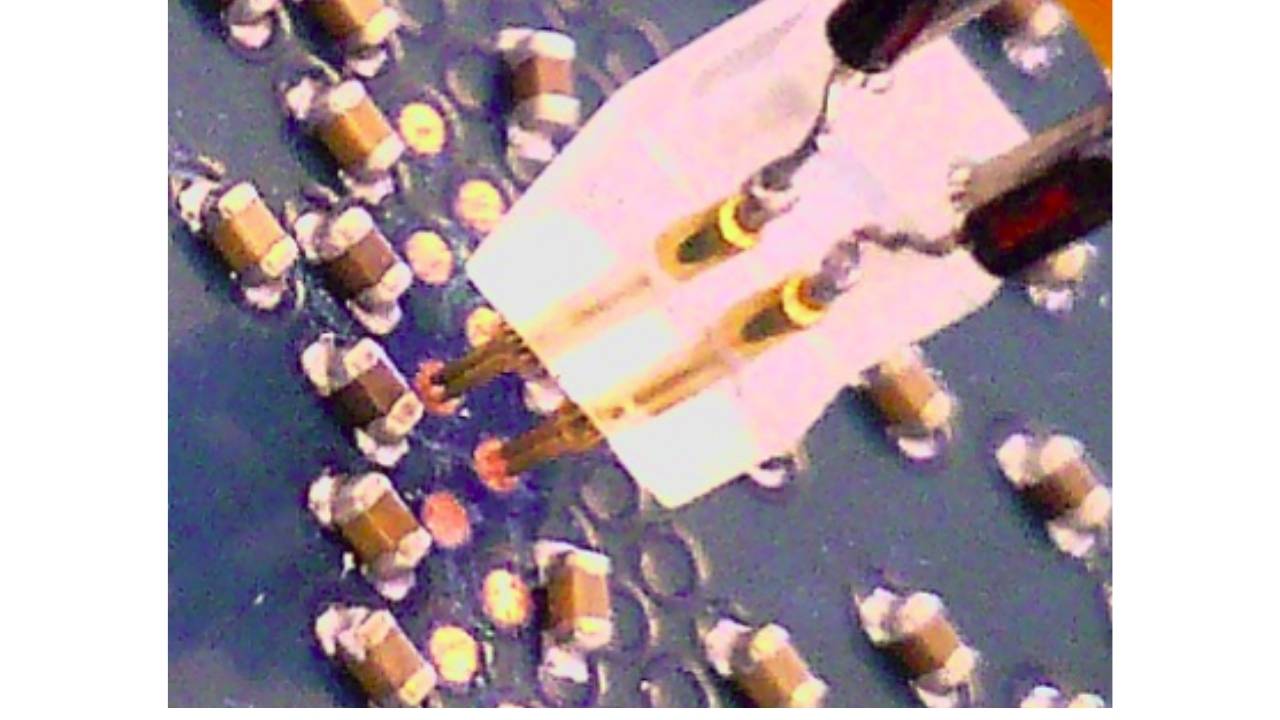

Load Board – Coaxial Connector Testing

Integrate mating Connector within Flying Prober to use for PCBA testing

Load Board – Performance Tests

-

▫️ RF Testing

-

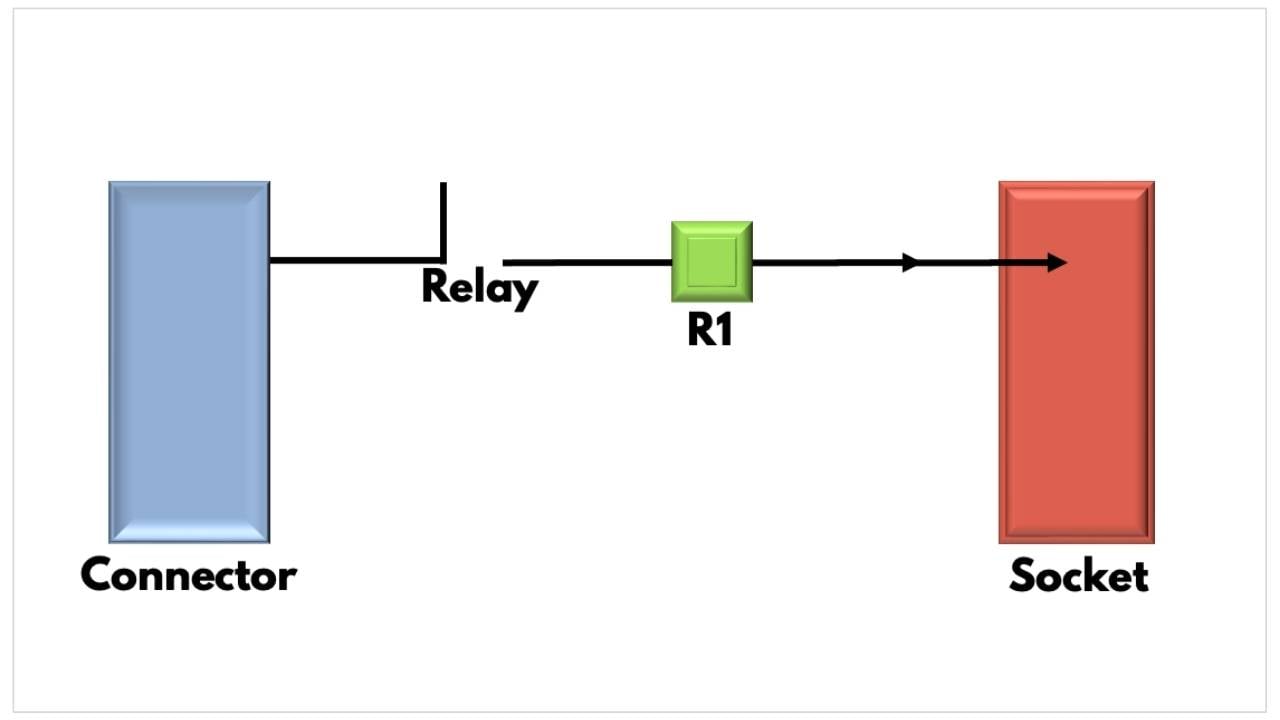

▫️ Channel Continuity Test

RF Testing

Measure frequencies up to 40Ghz with high precision placement on top and/or bottom side of PCBA.

Channel Continuity Test