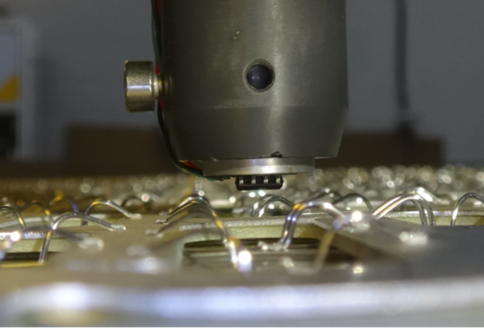

The Hover Sense non-contact probe module offers full test coverage without requiring direct access to the battery's anode or cathode.

Poor quality cell interconnects can lead to several problems, such as increased resistance, leading to increased heat generation, voltage drop, and reduced overall performance. Also poor interconnects can also lead to safety hazards such as arcing, which can cause fires or explosions. Battery cell interconnect issues must be caught during battery production.

Current test methods:

- rely on physical contact with the interconnects, risking damage

- optically check for visible defects and not electrical properties

- measure temperature variations and not electrical properties

Hover Sense non-contact uses advanced magnetic field measurement techniques to assess the interconnect quality without physical contact. This alleviates any concerns about battery surface degradation or probe markings.

Hover Sense non-contact probe module can be used to test both laser-welded and wire-bonded interconnects.

Highlights of the Hover Sense Non-Contact Technology

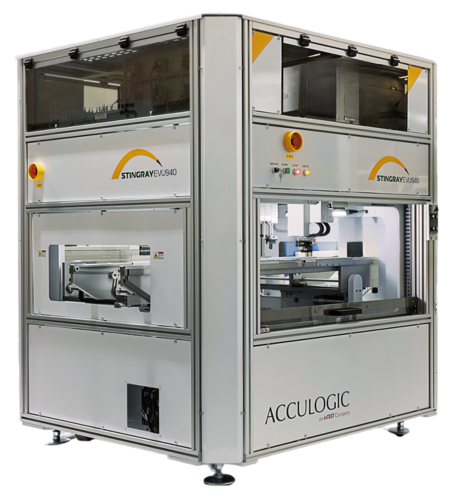

STINGRAY EVO500 Battery Tester

Extends test capabilities far beyond the typical detection of opens and near-opens with the versatility to accommodate up to 22 probe modules including both top and bottom probing.