Boundary Scan Solutions

Acculogic’s Boundary Scan Test and Programming tools seamlessly integrate into our systems.

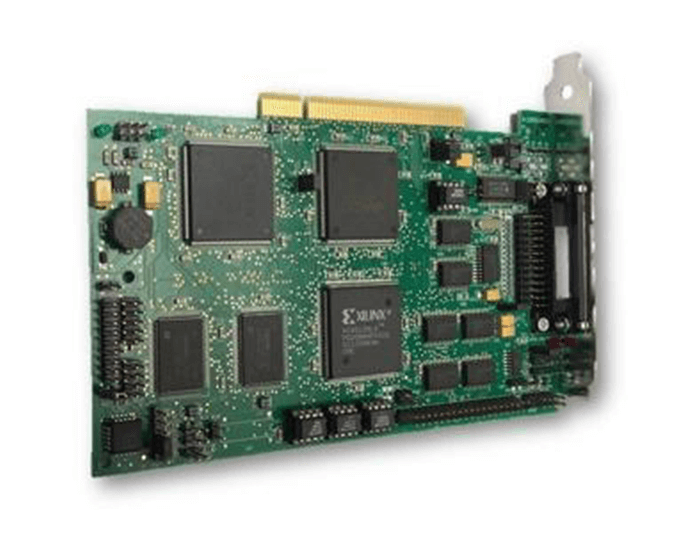

ScanMaster

ScanMaster is a boundary scan controller designed for design verification, production testing, and onboard device programming applications.

Features

Features

ScanBox

ScanBox combines a built-in Boundary Scan controller and PC-standard connectivity with the modularity and size reduction of card cage-based systems. ScanBox’s compact, flexible package and reliable operation meet the needs of R&D and manufacturing and test engineers delivering electronics for the aerospace/defense, automotive, industrial, medical, and consumer electronics markets.

Features

Features

ScanMultiplier

ScanMultiplier facilitates the test & programming of up to 16 targets, allowing any combination of up to 16 TAP channels. Its intelligent controller routes serial data streams to and from targets under program control, allowing any number of channels (from 1 to 16) to be selected and operated in sequence or parallel by the user.

Integrator Software

Integrator is the automatic test program generator (ATPG) and operating software, with built-in boundary scan, that manages all aspects of test program sequencing, debugging, optimizing, and execution on the Acculogic FLS980 DXi Flying Probe, STINGRAY EVO500, Briz, and functional test systems.