Automated Test & Measurement Solutions for Electronics Manufacturers

Acculogic designs and manufactures Automated Test Systems engineered to validate the quality of your circuit assemblies & electronics in minimal time with exceptional test coverage. Leading electronics companies worldwide trust and depend on Acculogic for their product test and quality validation requirements. Get products to market faster and achieve high test coverage with automated test equipment and validation systems that help you overcome your production test challenges and ship quality products on-time.

Accurately, Quickly, and Cost-effectively Validate Your Product Quality.

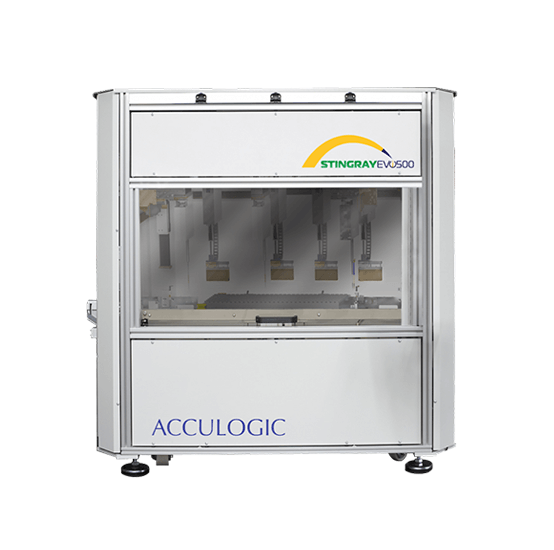

Flying Probe Robotic

Test System

Battery Interconnect

Tester

End-of-Line/Functional Test Systems

Services

Acculogic offers a broad range of services. From turn-key Automated Test Equipment (ATE) to test fixture design and fabrication. Our engineers can help you find or create the ultimate test strategy optimized for real production environments.

Learn More