Partner for Performance

High-speed production lines demand precision without compromise.

Integrating production with testing is the key to staying ahead in a competitive market.

By implementing automated battery interconnect testing, an automotive line integrator can ensure the highest levels of safety, quality, and efficiency, which are critical for maintaining competitiveness and meeting the evolving demands of the EV market.

Download our whitepaper to see how we've solved the challenge of testing laser welded battery interconnects!

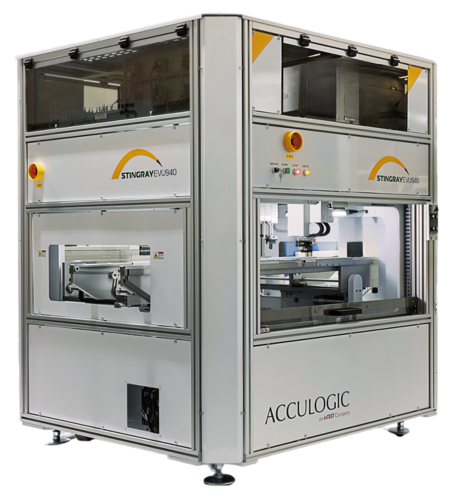

The Stingray EVO500 Battery Tester integrates seamlessly into production lines, enhancing efficiency, accuracy, and compliance with industry standards.

1. Speed: Automated systems can perform tests much faster than manual processes, reducing bottlenecks in the production line.

2. Improve Production Quality: Integrating advanced testing with laser welding ensures each weld meets stringent performance standards, resulting in higher-quality battery assemblies.

2. Improve Production Quality: Integrating advanced testing with laser welding ensures each weld meets stringent performance standards, resulting in higher-quality battery assemblies.

3. Quality Assurance: Automation ensures consistent application of testing parameters across all units, reducing variability in test results.

EV Battery Tester

The Stingray enables battery manufacturers to quickly, reliably, and cost-effectively test battery module interconnects.